1. The production of the sofa frame, the foundation Before the sofa starts to be produced, a master with rich experience is required to draw a good plan. Without a good model, it is impossible to make a good sofa. Because every connection requires meticulous calculations, the appearance that is almost made is not a little difference.

After the board is finished, the formal production of the sofa frame begins. The current sofa frame is mainly divided into two materials: solid wood and composite board. The frame of the sofa, in my opinion, is similar to the human skeleton, supporting the entire sofa. The firmness of the sofa frame structure and the rationality of the design angle will affect the quality and function of the sofa.

The following small series mainly introduce the production process of solid wood frame.

1. Dry the wood. Because wood contains moisture, the moisture content of wood is controlled within 12% by drying, which can greatly reduce the deformation rate of wood. Not easy to deform, rot and moth-eaten. 2. Open the material. Cut out the backrest, armrest and other parts according to the template drawing. After that, the wood is sanded, wind sheared, and edge trimmed. 3. Tenon reinforcement. The parts of the sofa frame are tightly combined by the tenon connection method.

The tenon-and-mortise technique has been passed down in China for thousands of years. If you have a set of old furniture at home, it must be spliced using the tenon-and-mortise technique. Otherwise, it won't be so strong. In addition, in order to strengthen the frame, each joint of the frame must be positioned with a precisely cut wooden tripod, and after connecting with gun nails or screws, it must be coated with white glue. (reinforced)

Here you need to pay attention to some small details, and the interface should be stitched precisely.

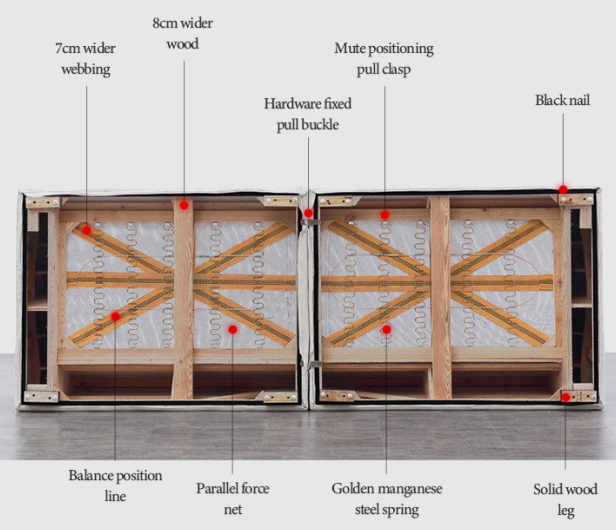

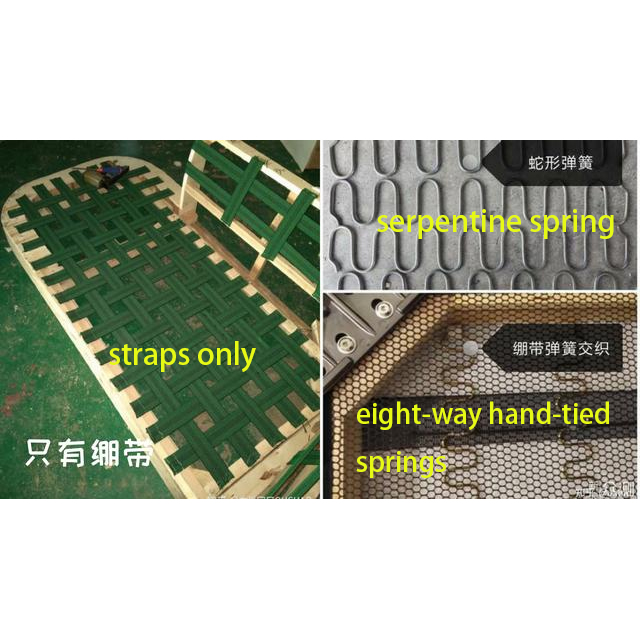

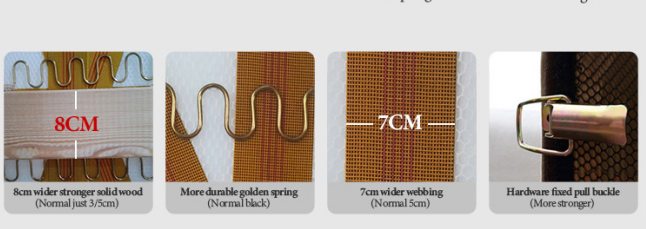

4. Bottom. Mainly adding springs and bandages to the sofa. Put elastic straps on the back of the sofa! Because the bearing capacity of the back frame is not as great as that of the seat frame, it is sufficient to use elastic straps. There are also so-called black belts, which are made from discarded tires.

Springs are generally made of serpentine springs (also called S-shaped springs) to increase the bearing capacity of the sofa, and then fixed with special spring clips to reduce noise. The spring installation must be firm, and there should be no change when pressing hard. Quantity depends on specific needs.

5. Covering cloth. The cushion area is covered with the breathable mesh cloth that you know, which can effectively prevent moisture and breath, and increase the life of the sofa.

2 Sofa padding The padding inside the sofa includes sponge, down and rayon. The types of sponges are mainly high, medium and low sponges with three different densities.

The sponge inside the sofa will be related to the sitting feeling of the sofa. The quality of the filled sponge will also affect the service life of the sofa.

Cut out different shapes of sponges according to the shape of the sofa.

Wrap the sponge around the sofa frame.

3 Coat cutting and sewing The sofa you see, each side is a board, which is called a leather board. Place the leather board on the cowhide to draw, and pay attention to avoid unqualified leather. Start cutting later. ▼

It can also be cut with a blade. Of course, if it is cloth, you can use electric scissors, and you can cut multiple layers at a time.

After the leather is cut, the sofa cushions, armrests, backrests, and backrests are sorted and packaged, so that the next "sewing" can be produced smoothly and efficiently.

Sewing, flat turning, joining the cut leather piece by piece, the sewing process is very important, and it is related to the appearance and craftsmanship of a sofa set.

Embossed line. Single needle car pressure line, single line and double line need to be pressed to the margin of 5 mm, the line is symmetrical on the left and right, straight and clear, and the direction is regular and uniform.

Press the line. The double-needle car presses the thread, and the fabrics are stacked on the joint of the flat car, and the double-needle car will overlap and sew firmly. The same is true for the entire coat production process of the fabric sofa. But cutting cloth is easier than cutting leather. But it's the same for skilled workers. 5 transfer with the door. Cover the sofa with the sewn sofa leather cover or cloth cover. According to the appearance of the sofa, fix it with gun nails according to the appropriate positioning. Fabric sofas need to be fitted with hardware such as zippers. After these processes are completed, you can see such a leather sofa...